With Catena-X, we want to connect companies across all sectors. End-to-end data networking from small and medium-sized enterprises to OEMs will help us to make important progress in the sustainability of our products and the resilience of our supply chains.

The first use cases are already being operationalized within this framework. Demand and capacity management, for example, ensures that bottlenecks are avoided through the digital, smooth coordination of demand and capacity along the supply chain. Additional potential areas of application are constantly being developed. The use of Data Spaces in conjunction with standardized connectors can, for example, help to greatly reduce the current high manual effort required to manage business partners at automotive OEMs by fully automating the exchange of collaboration information (e.g. contracts, certificates) via the Catena-X network.

Our Approach

How do we create the conditions for optimized partner integration for our customers?

For us, the first step is to specifically identify potential in the collaboration between our customer and its business partners along the process-related and technical realities. The reorganization of partner integrations requires an accompanying basic analysis of the current application landscape with a focus on systems, integrations and data on the part of Senacor. We scale freely according to the required scope of consideration, from individual integrations to holistic analyses of grown, complex integration landscapes.

What do we bring with us?

In order to develop a truly suitable target image with our customers, we use our content-related, technical and organizational knowledge of Catena-X and other Dataspace initiatives (such as Manufacturing-X). We also draw on our in-depth knowledge of the market in terms of existing individual and complex solutions for the integration of partners and build on our many years of cross-value-added automotive IT experience. In addition, we recommend and manage the accompanying integration of existing or planned (pilot) partner companies with whom the exchange of data is to be initiated or further developed at an early stage.

How do we create facts?

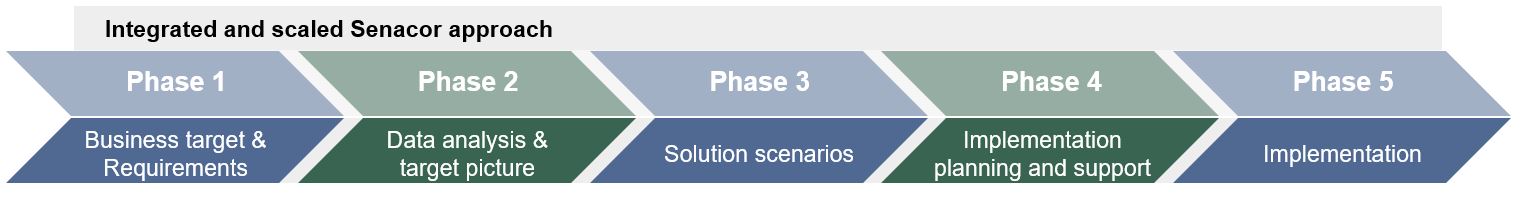

Of course, there is no ‘one-fits-all’ solution for reorganizing partner integrations. With the help of our integrated and scalable approach, our customers can achieve optimized partner integrations (e.g. via Catena-X) within a manageable time frame with the usual Senacor reliability and quality:

Phase 1: Business target & Requirements

- Design of required E2E use cases for connecting partners in line with Catena-X use cases

- Derivation of high-level requirements framework involving all systems and stakeholders

Phase 2: Data analysis & target picture

- Analysis of data scope per use case incl. transformation requirements from corporate to Catena-X level

- Support for standardization tasks along with the Catena-X consortium

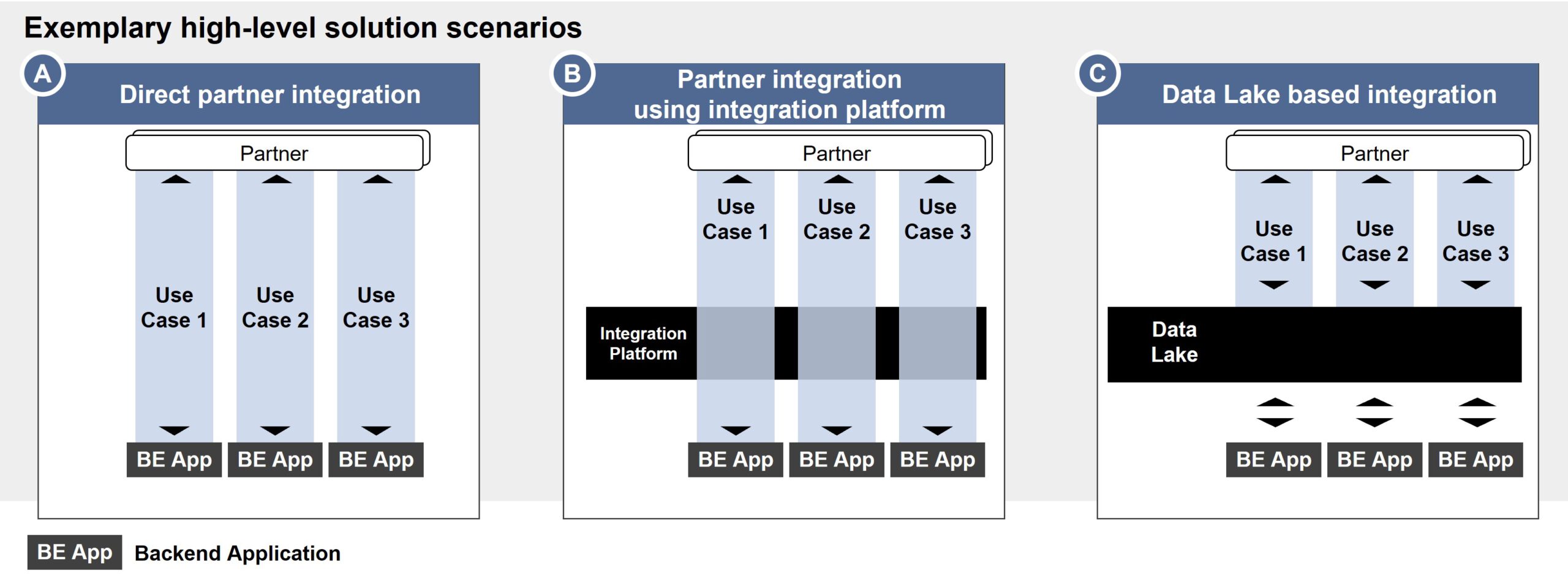

Phase 3: Solution scenarios

- Development of pragmatic solution scenarios suitable for the selected use case

- Detailing of target architecture (e.g. according to Togaf) and selection of suitable solution modules (make, buy, reuse) incl. localization of necessary technical components (e.g. EDC – Eclipse Dataspace Connector)

Phase 4: Implementation planning and support (incl. roadmap)

- Definition of necessary steps and milestones for the ideal implementation of partner integrations, including budget, resources, stakeholders and technologies

- Continuous tracking of development progress and integrated quality and schedule assurance

Phase 5: Implementation

- Qualitative implementation of required solution modules by experienced Senacor development teams

We scale all services within the Senacor approach together with our customers according to the required and desired professional and technical depth. In this way, we not only provide support as part of a comprehensive overall approach, but also in the targeted individual consideration of a self-contained use case.

Get in touch!

SEBASTIAN KOSCHINSKI

Partner Automotive